In a bold move that underscores the intensifying battle for memory chip supremacy, Micron Technology has broken ground on a massive $24 billion semiconductor facility in Singapore, marking one of the largest private investments in the city-state’s history. The American memory chipmaker’s expansion comes at a critical juncture as the global semiconductor industry grapples with unprecedented supply constraints driven by artificial intelligence’s insatiable appetite for advanced memory.

The new advanced wafer fabrication facility, announced Tuesday at a groundbreaking ceremony attended by Singapore’s Deputy Prime Minister Gan Kim Yong, represents a strategic bet on Asia’s manufacturing prowess even as the United States pushes to reshore semiconductor production. With 700,000 square feet of cleanroom space planned over the next decade, the facility is designed to address surging demand for NAND flash memory—the storage technology that has become increasingly critical to AI applications and data centers worldwide.

Build the future you deserve. Get started with our top-tier Online courses: ACCA, HESI A2, ATI TEAS 7, HESI EXIT, NCLEX-RN, NCLEX-PN, and Financial Literacy. Let Serrari Ed guide your path to success. Enroll today.

The Perfect Storm: When AI Demand Collides With Chip Capacity

The semiconductor industry is experiencing what analysts are calling an AI-driven memory supercycle—a period of explosive demand growth that has caught even the world’s largest chipmakers off guard. Unlike previous chip shortages that stemmed from pandemic-related disruptions, this crisis represents a fundamental restructuring of global memory production priorities.

At the heart of the shortage lies a zero-sum game in wafer allocation. Major memory manufacturers including Micron, Samsung Electronics, and SK Hynix are redirecting their limited fabrication capacity toward high-bandwidth memory (HBM)—specialized chips that power AI accelerators from companies like Nvidia and Advanced Micro Devices. This strategic pivot has created severe shortages in traditional NAND and DRAM products used in smartphones, laptops, and enterprise servers.

The numbers paint a stark picture. Industry research firm IDC projects that DRAM and NAND supply growth will lag below historical norms at 16% and 17% year-on-year respectively in 2026—far below the demand trajectory driven by AI infrastructure buildouts. TrendForce forecasts that conventional DRAM prices will surge 55-60% quarter-over-quarter in the first quarter of 2026, while NAND flash prices are expected to climb 33-38%.

For consumers and businesses, the impact is already being felt. Dell Technologies Chief Operating Officer Jeff Clarke warned that the company has “never witnessed costs escalating at the current pace,” with tighter availability across DRAM, hard drives, and NAND flash memory. Smartphone manufacturers are particularly vulnerable, with memory representing 15-20% of total manufacturing costs for mid-range devices.

Singapore: The Strategic Hub in Memory’s New Geography

Micron’s massive commitment to Singapore reflects the city-state’s emergence as a critical node in the global semiconductor supply chain. The company already produces 98% of its flash memory chips in Singapore, making it the primary manufacturing hub for NAND production. The new facility will become part of Micron’s NAND Center of Excellence, co-locating advanced manufacturing with research and development activities.

The investment builds on Micron’s earlier $7 billion commitment announced in early 2025 for an advanced packaging facility focused on high-bandwidth memory. That HBM packaging plant is on track to begin contributing meaningfully to supply in calendar year 2027, creating what Micron describes as opportunities for synergies between NAND and DRAM production at the same manufacturing complex.

Singapore’s attractiveness as a semiconductor hub stems from multiple factors beyond its skilled workforce and favorable business climate. The nation contributes nearly 7% to its GDP through semiconductor activities and employs over 35,000 people in the sector, which has grown at an 11% compound annual growth rate over the past decade. Recent geopolitical tensions and pandemic-related disruptions have accelerated “friend-shoring” strategies, with companies seeking to diversify production away from geopolitically sensitive regions.

“Micron’s latest expansion will strengthen our semiconductor ecosystem and further anchor Singapore as a critical node in the global semiconductor supply chain,” said Jermaine Loy, managing director of Singapore’s Economic Development Board. The city-state has attracted over S$18 billion in semiconductor investments in the past two years alone, with nine of the top 15 global semiconductor firms now operating facilities there.

The Manufacturing Timeline: A Race Against Shortage

Micron’s Singapore facility faces a challenging timeline. Wafer production is scheduled to begin in the second half of calendar year 2028, meaning relief for the current memory shortage remains years away. The facility will be Singapore’s first double-story wafer manufacturing fab—a design innovation aimed at maximizing land efficiency while providing the necessary cleanroom capacity.

The new NAND expansion is expected to create approximately 1,600 jobs in fab engineering and operations, incorporating AI, advanced robotics, and smart manufacturing technologies. Combined with the 1,400 positions tied to the HBM packaging facility, Micron’s expansion will support about 3,000 new jobs total in Singapore.

However, critics point out that by 2028, the memory landscape may have evolved significantly. The facility’s long lead time means Micron must make critical technology bets today about what the market will demand half a decade from now. The company has indicated it will maintain flexibility in managing capacity ramps to align with market demand—a hedge against potential oversupply scenarios that have plagued the cyclical memory industry in past downturns.

The Competitive Landscape: Korean Giants Take Different Paths

Micron’s aggressive NAND expansion stands in stark contrast to strategies pursued by its Korean competitors. Both Samsung and SK Hynix have reportedly scaled back NAND production in the second half of 2025, with Samsung weighing price hikes of 20-30% as it negotiates 2026 supply contracts. The Korean giants are prioritizing capital expenditure toward DRAM and HBM production rather than NAND expansion.

According to industry reports, SK Hynix plans to increase DRAM capacity to approximately 600,000 wafers per month by late 2026—nearly double its 2023 levels—while keeping NAND investment muted. Samsung similarly is focusing growth investments on DRAM and HBM, with NAND capital expenditure representing only about 10% of total spending in 2026.

This divergence in strategy creates an opening for Micron. While Samsung and SK Hynix control significant market share in NAND—Samsung is the world’s largest NAND manufacturer—their shift toward higher-margin HBM and DRAM products leaves gaps in traditional NAND supply. Micron’s willingness to invest heavily in NAND capacity at this juncture could position the company to capture market share as competitors pull back.

The competitive dynamics are further complicated by Chinese manufacturers, who have aggressively pursued low-cost strategies in consumer NAND products. This price pressure has accelerated the shift among established players toward enterprise SSDs and data center applications, where margins remain more attractive.

One decision can change your entire career. Take that step with our Online courses in ACCA, HESI A2, ATI TEAS 7, HESI EXIT, NCLEX-RN, NCLEX-PN, and Financial Literacy. Join Serrari Ed and start building your brighter future today.

The American Dimension: Balancing Asia and Domestic Production

Micron’s massive Singapore investment comes amid unprecedented efforts to rebuild American semiconductor manufacturing capacity. Just weeks before the Singapore groundbreaking, Micron officially broke ground on a $100 billion megafab complex in Onondaga County, New York—the largest private investment in New York State history.

The New York facility, which will eventually house up to four fabs spanning 2.4 million square feet, represents the cornerstone of Micron’s goal to produce 40% of its DRAM in the United States by the 2040s. The project, supported by $6.4 billion in CHIPS Act direct funding and $5.5 billion in state incentives, is expected to create 50,000 jobs and position Central New York as a global leader in advanced memory manufacturing.

“By breaking ground on Micron’s New York megafab, we are taking another important step in creating a future where the most critical components of the AI economy are built on American soil,” said Micron Chairman, President and CEO Sanjay Mehrotra during the January ceremony. However, production at the New York site won’t begin until the end of the decade, highlighting the long lead times inherent in semiconductor fab construction.

Micron’s dual-track approach—investing heavily in both Singapore and New York—reflects the complex geopolitical and economic realities facing global chipmakers. While the United States pushes to reshore critical semiconductor production for national security reasons, Asia retains significant advantages in manufacturing expertise, supply chain ecosystems, and cost structures. Singapore, as a politically stable, business-friendly nation with deep semiconductor expertise, offers an attractive middle ground.

The company’s broader U.S. expansion vision encompasses approximately $200 billion in investments, including two leading-edge fabs in Idaho, the New York complex, modernization of Virginia facilities, and advanced HBM packaging capabilities. To accelerate timeline, Micron also acquired a fab facility from Taiwan’s Powerchip Semiconductor for $1.8 billion, planning to retrofit it for DRAM production by mid-to-late 2027.

The Technology Evolution: NAND’s Growing Role in AI Infrastructure

While much attention in the memory shortage has focused on HBM and DRAM, NAND flash technology is quietly becoming increasingly critical to AI infrastructure. The storage technology, which forms the backbone of solid-state drives (SSDs), is experiencing surging demand as data centers upgrade to support AI workloads that require both high-speed processing and massive data storage capacity.

AI training and inference workloads generate and consume enormous volumes of data. Unlike traditional computing applications, AI systems often require rapid access to training datasets that can reach hundreds of terabytes or even petabytes. This has driven accelerated demand for enterprise SSDs, which TrendForce projects will become the largest NAND flash application segment in 2026, surpassing consumer client SSDs.

The technology requirements for AI applications are also evolving. Nvidia’s recent launch of its Rubin platform has boosted expectations for AI SSDs that use PSLC (Pseudo Single-Level Cell) mode. While this approach improves speed and durability, it reduces actual storage capacity by two-thirds—meaning suppliers must increase physical wafer input by 3-4 times to maintain the same effective capacity. This amplification effect further exacerbates NAND supply constraints.

Micron’s Singapore facility will focus on advanced NAND technology nodes designed for these demanding applications. The company has indicated the facility will integrate advanced process technologies and leverage synergies with its HBM packaging operations at the same site. This co-location strategy could enable innovations in hybrid memory-storage architectures optimized for AI workloads.

Market Implications: The Price Surge and Strategic Response

The memory shortage has triggered what some analysts describe as the most dramatic price escalation in semiconductor history. Contract prices for 16Gb DDR5 DRAM chips surged from approximately $6.84 in September 2025 to $27.20 by December—a nearly 300% increase in just three months, according to industry data. NAND flash has experienced similar volatility, with SSD prices roughly doubling in recent months.

For smartphone manufacturers and PC makers, the crisis has forced difficult choices. Some are downgrading specifications to reduce bill-of-materials costs, while others are passing price increases to consumers. Lenovo has publicly acknowledged stockpiling DRAM and NAND components to ensure supply through end of 2026, with memory inventories approximately 50% above normal levels.

The supply constraints have created clear winners and losers. Apple, which secured long-term supply agreements, has weathered the shortage better than competitors. Samsung’s president warned that memory chip shortages will affect pricing industry-wide in 2026, acknowledging that even the world’s largest memory manufacturer cannot insulate its products from the surge.

Investment banks have revised their outlooks accordingly. Morgan Stanley projects DRAM and NAND prices rising 62% and 75% respectively on average for 2026, while downgrading PC and server manufacturers due to margin pressures. Conversely, memory manufacturers are reaping record profits. Bank of America defines 2026 as a “[supercycle similar to the boom of the 1990s](https://www.axtekic.com/news/global-dram-and-nand-market-outlook-2025%E2%80%932026:-ai-demand-sparks-new-wave-of-price-hike s.html),” forecasting DRAM revenue to surge 51% and NAND by 45% year-over-year.

Looking Ahead: Relief Delayed But Not Denied

Industry experts broadly agree that relief from the current memory shortage will not arrive quickly. Multiple forecasts suggest tight supply conditions will persist through at least 2027, with some predicting constraints extending into 2028. The timeline depends on multiple factors: the pace of capacity additions from new fabs, the trajectory of AI infrastructure investment, and potential demand destruction from high prices.

Micron CEO Sanjay Mehrotra stated during the company’s Q1 2026 earnings call that “we believe that the aggregate industry supply will remain substantially short of the demand for the foreseeable future.” This assessment is shared across the industry. SK Hynix reported that its HBM, DRAM, and NAND capacity is “essentially sold out” for 2026, while Micron recently exited the consumer memory market entirely to focus on enterprise and AI customers.

The supply-demand imbalance is creating structural changes that may persist beyond the current crisis. Memory manufacturers are investing heavily in next-generation technologies—HBM4, advanced DRAM nodes, and high-layer-count 3D NAND—rather than expanding capacity for legacy products. This creates particular challenges for industries like automotive and industrial equipment that rely on mature memory technologies with long product lifecycles.

For Micron, the Singapore investment represents a calculated bet that NAND demand will remain robust through the decade as AI continues scaling and data-centric applications proliferate. The company’s willingness to commit $24 billion to NAND capacity while competitors prioritize DRAM and HBM suggests confidence in differentiated positioning. If the bet pays off, Micron could emerge from this cycle with strengthened market position in an essential but under-invested segment.

The Broader Implications: Reshaping the Global Memory Landscape

Micron’s Singapore expansion is more than a single company’s capital allocation decision—it reflects fundamental shifts reshaping the global memory industry. The semiconductor sector is moving from the cyclical boom-bust patterns that characterized previous decades toward a new paradigm where strategic capacity allocation, geopolitical considerations, and technology transitions create persistent supply-demand imbalances.

The geographic distribution of memory manufacturing is evolving rapidly. While Asia—particularly South Korea, Taiwan, Japan, and Singapore—remains dominant, the United States is clawing back share through CHIPS Act incentives and national security imperatives. By the end of the decade, state officials project that one in four U.S.-made chips will be produced within 350 miles of Upstate New York, dramatically altering the industry’s center of gravity.

The memory shortage has also accelerated innovation in alternative technologies and architectures. Researchers are exploring optical and DNA-based storage for archival applications, potentially alleviating pressure on NAND for long-term data retention. Companies are developing more memory-efficient AI algorithms and hardware architectures to reduce dependence on scarce components.

For Singapore, Micron’s expanded commitment validates its decades-long strategy to position itself as an indispensable hub in global technology supply chains. The city-state’s political stability, skilled workforce, and pro-business environment have attracted investments not just from Micron but from companies across the semiconductor ecosystem, from wafer fabrication to advanced packaging to equipment manufacturing.

As Micron’s CEO Mehrotra noted at the groundbreaking ceremony, “As AI continues to scale, memory and storage are no longer just components within a system. They have become strategic assets that absolutely enable the potential of AI.” This recognition—that memory chips are now infrastructure as critical as energy grids or transportation networks—helps explain why governments and companies are willing to commit hundreds of billions of dollars to reshape the global memory landscape.

The next few years will test whether these massive investments arrive in time to meet surging demand, or whether the memory shortage will constrain the pace of AI development and digital transformation. Micron’s $24 billion bet on Singapore places the company at the center of that crucial question, with implications extending far beyond any single fab or city-state to the future trajectory of the global digital economy.

Ready to take your career to the next level? Join our Online courses: ACCA, HESI A2, ATI TEAS 7 , HESI EXIT , NCLEX – RN and NCLEX – PN, Financial Literacy!🌟 Dive into a world of opportunities and empower yourself for success. Explore more at Serrari Ed and start your exciting journey today! ✨

Track GDP, Inflation and Central Bank rates for top African markets with Serrari’s comparator tool.

See today’s Treasury bonds and Money market funds movement across financial service providers in Kenya, using Serrari’s comparator tools.

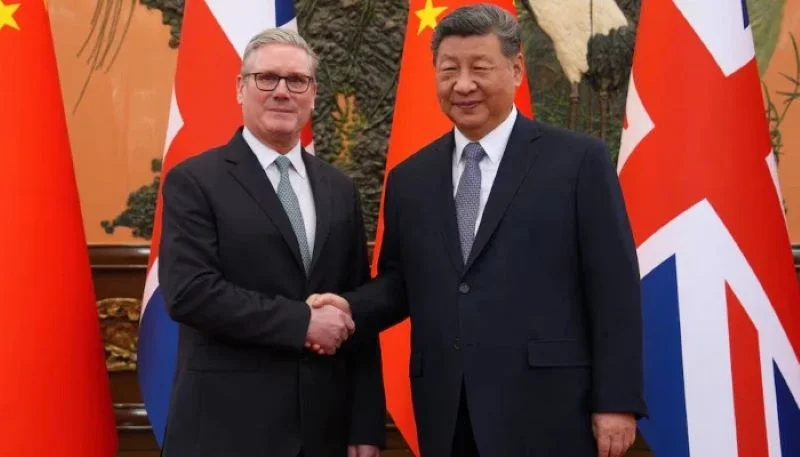

photo source: Google

By: Montel Kamau

Serrari Financial Analyst

28th January, 2026

Article, Financial and News Disclaimer

The Value of a Financial Advisor

While this article offers valuable insights, it is essential to recognize that personal finance can be highly complex and unique to each individual. A financial advisor provides professional expertise and personalized guidance to help you make well-informed decisions tailored to your specific circumstances and goals.

Beyond offering knowledge, a financial advisor serves as a trusted partner to help you stay disciplined, avoid common pitfalls, and remain focused on your long-term objectives. Their perspective and experience can complement your own efforts, enhancing your financial well-being and ensuring a more confident approach to managing your finances.

Disclaimer: This article is for informational purposes only and does not constitute financial advice. Readers are encouraged to consult a licensed financial advisor to obtain guidance specific to their financial situation.

Article and News Disclaimer

The information provided on www.serrarigroup.com is for general informational purposes only. While we strive to keep the information up to date and accurate, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability, or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

www.serrarigroup.com is not responsible for any errors or omissions, or for the results obtained from the use of this information. All information on the website is provided on an as-is basis, with no guarantee of completeness, accuracy, timeliness, or of the results obtained from the use of this information, and without warranty of any kind, express or implied, including but not limited to warranties of performance, merchantability, and fitness for a particular purpose.

In no event will www.serrarigroup.com be liable to you or anyone else for any decision made or action taken in reliance on the information provided on the website or for any consequential, special, or similar damages, even if advised of the possibility of such damages.

The articles, news, and information presented on www.serrarigroup.com reflect the opinions of the respective authors and contributors and do not necessarily represent the views of the website or its management. Any views or opinions expressed are solely those of the individual authors and do not represent the website's views or opinions as a whole.

The content on www.serrarigroup.com may include links to external websites, which are provided for convenience and informational purposes only. We have no control over the nature, content, and availability of those sites. The inclusion of any links does not necessarily imply a recommendation or endorsement of the views expressed within them.

Every effort is made to keep the website up and running smoothly. However, www.serrarigroup.com takes no responsibility for, and will not be liable for, the website being temporarily unavailable due to technical issues beyond our control.

Please note that laws, regulations, and information can change rapidly, and we advise you to conduct further research and seek professional advice when necessary.

By using www.serrarigroup.com, you agree to this disclaimer and its terms. If you do not agree with this disclaimer, please do not use the website.

www.serrarigroup.com, reserves the right to update, modify, or remove any part of this disclaimer without prior notice. It is your responsibility to review this disclaimer periodically for changes.

Serrari Group 2025