Kenya stands at a critical juncture for industrial development as the Ministry of Investments, Trade and Industry confronts multiple structural challenges threatening the country’s manufacturing competitiveness and export growth potential. Cabinet Secretary Lee Kinyanjui’s urgent call for the release of billions of shillings in delayed Value Added Tax refunds to companies represents just one dimension of a broader policy crisis that encompasses geographic concentration of manufacturing activity, data credibility disputes, and shifting global trade dynamics.

Speaking at a two-day workshop for senior ministry officials organized by the Kenya Bureau of Standards at Sawela Lodge in Naivasha, CS Kinyanjui emphasized that delayed VAT refunds running into billions of shillings are eroding investor confidence and derailing planned expansion projects across multiple sectors. The CS revealed that his ministry is actively working on reviewing VAT rates for exports while simultaneously engaging the Kenya Revenue Authority to urgently address the refund backlog that has become what he termed “one of the biggest challenges currently facing companies.”

The intervention signals government recognition that administrative inefficiency in processing export-related VAT refunds threatens to undermine broader industrialization objectives and Kenya’s competitiveness in regional and global markets at precisely the moment when new opportunities are emerging from shifting trade patterns and market access agreements.

Build the future you deserve. Get started with our top-tier Online courses: ACCA, HESI A2, ATI TEAS 7, HESI EXIT, NCLEX-RN, NCLEX-PN, and Financial Literacy. Let Serrari Ed guide your path to success. Enroll today.

Manufacturing Concentration Creates Regional Inequality and Economic Vulnerability

Beyond the immediate VAT refund crisis, Kenya’s industrial development faces fundamental structural challenges around the extreme geographic concentration of manufacturing activity. Industry Principal Secretary Juma Mukhwana highlighted that six counties—Nairobi, Mombasa, Kiambu, Nakuru, Machakos, and Kisumu—host 90 percent of manufacturing companies in the country, creating pronounced regional disparities that undermine both economic efficiency and political sustainability of industrial policy.

The concentration pattern is even more extreme when examining specific county contributions to manufacturing output. According to Kenya National Bureau of Statistics data on Gross County Product, Nairobi County contributed an average of 36.9 percent to overall manufacturing gross value added between 2018 and 2022, a dominance that represents more than one-third of national manufacturing output from a single administrative unit.

Following Nairobi, Mombasa contributed 9.6 percent, Kiambu 8.4 percent, Machakos 7.8 percent, and Kilifi 4.6 percent to manufacturing GVA over the same period. Together, these five counties accounted for 67.3 percent of total manufacturing GDP—leaving the remaining 42 counties to share less than one-third of national manufacturing output. This concentration is even more pronounced than overall economic output, where Nairobi contributed 27.5 percent to national GDP, followed by Kiambu at 5.6 percent, Nakuru at 5.2 percent, and Mombasa at 4.8 percent.

The Nairobi Metropolitan Area—comprising Nairobi, Kiambu, Machakos, and Kajiado counties—accounts for approximately 90 percent of Kenya’s industrial space, with Nairobi County alone holding 66 percent market share. This extreme concentration reflects rational business calculations around infrastructure access, proximity to transportation hubs including Jomo Kenyatta International Airport, availability of skilled labor, and connectivity to domestic and export markets.

However, the resulting regional inequalities create both economic and political challenges. Counties lacking manufacturing presence struggle to generate employment for growing populations, miss tax revenues that could fund local development, and see their youth migrate to manufacturing centers in search of opportunities. The geographic concentration also creates vulnerability to localized shocks—infrastructure failures, labor disputes, or security challenges affecting Nairobi and its environs disproportionately impact national manufacturing output.

PS Mukhwana’s call to “devolve” manufacturing recognizes that current concentration patterns are neither economically optimal nor politically sustainable in a devolved governance system where county governments bear responsibilities for local economic development but lack the industrial base to generate resources or employment at scale.

Floriculture Sector Illustrates Both Opportunities and Challenges

The floriculture industry provides a revealing case study of both Kenya’s competitive advantages and the challenges threatening industrial sustainability. CS Kinyanjui identified flowers as among major products that could propel the economy further as global demand and new markets continue emerging. His observation that many companies are fleeing Colombia due to high labor costs and eyeing land in Kenya represents what he termed “a blessing in disguise” for the country.

Kenya’s flower industry contributes approximately 1.5 percent to national GDP and employs over 150,000 people directly plus an estimated 2 million indirectly, with multiplier effects between 8 and 10. The sector generates approximately $1 billion in annual foreign exchange earnings, ranking as one of the top earners alongside tea and coffee exports.

Kenya enjoys natural competitive advantages for floriculture including fertile volcanic soil at appropriate altitudes, year-round sunshine enabling continuous production, access to freshwater sources in key growing regions, and proximity to Nairobi’s international airport facilitating rapid export of perishable products to European markets. Along with Ecuador and Colombia, Kenya occupies a unique position in global floriculture value chains serving primarily European and North American markets.

However, the sector faces mounting challenges that illustrate broader industrial competitiveness issues. Competition from Ethiopia, Colombia, and Ecuador has intensified, with these countries offering lower production costs and more favorable trade agreements. Rising labor costs in Kenya, driven partly by government-mandated deductions including the Social Health Insurance Fund, Housing Levy, and increased NSSF contributions, have reduced workers’ take-home pay while increasing employer costs.

The Kenya Flower Council CEO Clement Tulezi has highlighted that unpredictable taxation policies and multiple levies are making it difficult for the sector to remain competitive globally. The shift toward short-term and seasonal contracts to manage costs has undermined job security and labor protections, creating social costs that offset some of the industry’s economic benefits.

Climate change introduces additional variables through erratic rainfall patterns and rising temperatures that disrupt traditional growing cycles. Water scarcity concerns around Lake Naivasha—the center of Kenya’s floriculture production—have led to increased regulatory scrutiny and potential restrictions on water abstraction that could constrain further expansion. Stringent European Union regulations on pesticide residues and labor standards, while appropriate for sustainability and workers’ rights, create compliance costs that smaller Kenyan producers struggle to absorb.

The post-pandemic period has proven particularly challenging, with multiple flower companies scaling back operations, laying off workers, or exiting Kenya altogether due to surging production costs, shrinking European demand, and regulatory pressures. Yet industry resilience remains evident—Dutch investor Marginpar acquired several struggling farms in 2023, preserving hundreds of jobs, while other firms have diversified into higher-value varieties or invested in automation and sustainability measures to maintain competitiveness.

Tea Export Markets Undergo Strategic Reorientation

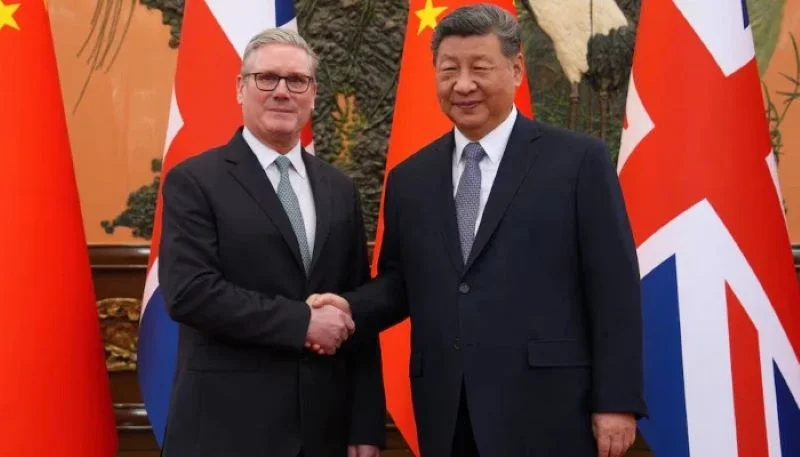

CS Kinyanjui noted significant shifts in Kenya’s tea export patterns that illustrate both challenges and opportunities in global agricultural commodity markets. For years, the country relied on Iran, India, and Iraq as traditional tea markets, but geopolitical changes necessitate strategic pivots. “With political changes in some countries like Iran, we are now seeking new markets like China where demand for tea is on the rise,” the CS explained.

China’s decision to allow Kenyan goods to enter its market duty-free demonstrates commitment to strengthening bilateral trade ties and creates substantial new opportunities for tea exporters. Kenya’s exports to China include agricultural products like tea, coffee, and avocados, plus metals including titanium ore, while the country imports machinery, electronics, and vehicles from Chinese manufacturers.

The tea sector’s pivot toward Asian markets and away from traditional Middle Eastern destinations reflects the pragmatic market diversification that CS Kinyanjui emphasized as critical for maintaining export growth amid volatile geopolitical conditions. However, success in new markets requires understanding different consumer preferences, building distribution relationships, and potentially adjusting product specifications to match varied demand profiles across markets.

African Growth and Opportunity Act Extension Provides Temporary Relief

On the critical matter of market access to the United States, CS Kinyanjui expressed confidence that ongoing negotiations would yield favorable outcomes and secure an additional three-year extension of the African Growth and Opportunity Act. The U.S. House of Representatives recently passed legislation extending AGOA by three years with a strong bipartisan vote of 340 to 54, offering relief to more than 80,000 Kenyans directly employed in apparel and textile firms plus approximately 250,000 others indirectly supported by the sector.

The extension eases uncertainty that had affected investment and expansion planning in industries heavily dependent on duty-free access to U.S. markets. Kenya ranks among AGOA’s leading beneficiaries, with apparel and textiles accounting for the bulk of exports to America alongside coffee, tea, and horticultural products. The program, enacted in 2000, allows eligible African countries to export a wide range of products to the United States duty-free, supporting trade, investment, and employment in participating nations.

However, the extension represents only temporary relief rather than permanent resolution of market access uncertainty. Kenya is simultaneously pursuing bilateral trade agreement negotiations with the United States aimed at expanding market access beyond textiles and diversifying export categories. These negotiations represent strategic efforts to institutionalize trade relationships beyond time-limited preference programs subject to periodic political renewal uncertainties that complicate long-term business planning.

The parallel challenge involves recent U.S. tariff policies that have created mixed implications for Kenyan exporters. While Kenyan goods now face new 10 percent tariffs, this rate remains significantly lower than tariffs imposed on key textile competitors like Vietnam (46 percent), Sri Lanka (44 percent), Bangladesh (37 percent), China (34 percent), Pakistan (29 percent), and India (26 percent).

CS Kinyanjui characterized the 10 percent tariff as “a hurdle, not a wall,” suggesting Kenya could position itself as an alternative sourcing hub for U.S. buyers seeking to avoid higher costs from traditional suppliers. This comparative advantage creates opportunities for investment in local textile production and value addition that could attract businesses relocating from higher-tariff jurisdictions. Industries including apparel, leather, and agro-processing could benefit from increased demand if Kenya can effectively market its relative tariff advantage while addressing domestic cost competitiveness challenges.

One decision can change your entire career. Take that step with our Online courses in ACCA, HESI A2, ATI TEAS 7, HESI EXIT, NCLEX-RN, NCLEX-PN, and Financial Literacy. Join Serrari Ed and start building your brighter future today.

Data Credibility Crisis Complicates Evidence-Based Policymaking

An unusual dimension of Kenya’s industrial policy challenges involves disputes over data credibility that significantly complicate evidence-based policymaking. CS Kinyanjui’s public criticism during the Kenya Association of Manufacturers priority agenda launch that manufacturers allegedly maintain multiple sets of financial records, presenting different figures depending on which government institution requests information, raises serious questions about the informational foundation for industrial policy.

“The lack of credible data makes it difficult for the government to make precise decisions,” Kinyanjui stated, emphasizing need for reliable standardized information to guide policy formulation and ensure targeted support for the sector. If manufacturers genuinely submit inconsistent data to tax authorities, statistical agencies, licensing bodies, and industry associations, this practice undermines government’s ability to assess sector performance, identify constraints, and calibrate interventions appropriately.

However, the data inconsistency issue may be more nuanced than deliberate manipulation. Different government institutions employ different methodologies, definitions, and reporting frameworks that can produce legitimately different results even from the same underlying economic activity. Tax filings follow specific accounting standards defined by revenue law. Statistical surveys may use different definitions of manufacturing output, employment, or value added. Industry association data might capture different company populations than official business registries. Reconciling these methodological differences requires sustained technical effort that neither government nor industry may prioritize adequately.

Regardless of root causes, CS Kinyanjui correctly identified that lack of authoritative data hampers precise policymaking. Without confidence in baseline statistics about manufacturing employment, output, exports, investment, and productivity, policymakers struggle to track whether interventions are achieving intended effects, identify emerging problems requiring attention, or justify resource allocations to particular sectors or regions.

The CS emphasized urgency in addressing the data challenge: “One of the biggest challenges facing the country is lack of one source of data mainly in the industrial sector and we should urgently address this.” Creating authoritative comprehensive industrial data systems would require sustained investment in statistical capacity across relevant government agencies, coordination mechanisms to harmonize methodologies and definitions, cooperation from manufacturers in providing accurate timely information, and data validation procedures ensuring quality and consistency.

The workshop setting at Sawela Lodge organized by Kenya Bureau of Standards—bringing together senior ministry leadership—suggests institutional recognition that policy effectiveness requires not just political commitment but robust data systems and analytical capacity supporting evidence-based decision-making.

Ministry Priorities Emphasize Employment Creation and Local Production Support

CS Kinyanjui challenged senior ministry officers to help government actualize its agenda through provision of employment and support for locally manufactured goods. This dual emphasis on job creation and domestic industrial development reflects recognition that manufacturing expansion serves both economic and social policy objectives in a country where youth unemployment remains chronically elevated and import dependency undermines foreign exchange stability.

The ministry would play a critical role in accelerating economic growth which would result in increased employment opportunities and revenue generation, the CS emphasized. However, translating strategic vision into operational reality requires addressing the structural impediments—VAT refund delays, geographic concentration, infrastructure deficits, regulatory unpredictability—that currently obstruct rather than enable industrial development.

Supporting locally manufactured goods involves complex policy choices around tariff protection, procurement preferences, quality standards, and competition policy. CS Kinyanjui has previously defended new and higher taxes on imported goods including vehicles, electronics, shoes, suits, tires, and mobile phones, arguing Kenya cannot reduce unemployment or poverty without deliberately protecting and growing local manufacturing capacity.

Drawing parallels with South Korea’s development model, the CS noted that approximately 60 percent of that economy is driven by family-owned corporations including Samsung, Hyundai, and LG, suggesting Africa should similarly nurture domestic industrial families rather than relying on multinational corporations or imports. While the protectionist logic has economic merit in principle, execution matters critically—protecting domestic industry through import barriers without simultaneously resolving structural obstacles like VAT refund delays creates policy environments that impose costs without delivering promised benefits.

Manufacturers need both protection from unfair import competition and efficient administration of export incentive mechanisms, competitive input costs, reliable infrastructure, and stable regulatory frameworks. Policy coherence across these dimensions determines whether industrialization strategies succeed in generating employment and economic transformation or fail to overcome entrenched structural constraints.

Infrastructure and Logistics Determine Industrial Location Patterns

The extreme concentration of manufacturing in Nairobi Metropolitan Area and a handful of other counties reflects infrastructure and logistics realities that policy interventions must address to achieve geographic diversification. Areas commanding highest industrial rents—Ruaraka, Industrial Area, and Mombasa Road averaging Ksh 450-550 per square meter—benefit from strategic locations near critical infrastructure including Jomo Kenyatta International Airport, Standard Gauge Railway stations, Inland Container Depot, and proximity to city center.

These locations have traditionally dominated industrial activity, benefiting from highest concentration of manufacturing developments that create agglomeration economies—clusters of related firms generating specialized labor pools, supplier networks, and knowledge spillovers that reduce costs and increase productivity. Ruiru, hosting Tatu City, Northlands City, and Nairobi Gate industrial developments, commands average rents of Ksh 409 per square meter reflecting its emergence as secondary industrial hub with improving infrastructure.

While Nairobi has long been Kenya’s industrial center, recent investments have shifted toward surrounding areas in Kiambu and Machakos counties largely due to establishment of Special Economic Zones offering tax incentives and streamlined approvals, improved infrastructure networks including roads and utilities, and greater availability and affordability of land compared to congested Nairobi. Higher manufacturing output in counties with Export Processing Zones reflects attractive opportunities and incentives these designated areas provide to investors establishing export-oriented businesses.

According to Export Processing Zones Authority, incentives include tax holidays exempting new investments from corporate taxation for initial years, duty exemptions on imported capital equipment and raw materials, quick approvals and licensing reducing bureaucratic delays, and infrastructure provision including utilities, roads, and customs facilities. These incentives partially offset infrastructure and services deficits that would otherwise deter investment in secondary locations.

Counties without EPZs and adequate infrastructure face systematic disadvantages attracting manufacturing investment regardless of other potential advantages like land availability or labor supply. Achieving the geographic diversification PS Mukhwana advocated requires either replicating EPZ-style incentive packages across more counties or significantly upgrading infrastructure and services in secondary cities to levels approaching those available in Nairobi Metropolitan Area.

The government’s ongoing development of Konza Technology City—spanning Machakos, Makueni, and Kajiado counties and including light industrial components—represents one approach to creating new industrial poles outside traditional centers. However, such initiatives require sustained infrastructure investment, policy consistency, and time horizons measured in decades rather than electoral cycles to achieve transformative impact on manufacturing location patterns.

Balancing Competitiveness and Revenue Needs

The VAT refund crisis and broader taxation challenges facing manufacturers illustrate fundamental tension between government revenue needs and industrial competitiveness imperatives. Manufacturers advocate for refunds amounting to Sh4 billion per month, while National Treasury allocates only Sh2.5 billion monthly—creating Sh1.5 billion shortfall that compounds refund backlogs every month.

From Treasury perspective, expediting refund processing creates immediate fiscal costs that must compete with other priorities including debt service, recurrent expenditures, and development projects. Using delayed refunds as de facto short-term financing provides budget flexibility that strict adherence to refund timelines would eliminate. However, this fiscal management approach extracts real costs from exporters that undermine competitiveness while signaling to investors that government priorities administrative convenience over supporting productive private sector activity.

International comparisons underscore that efficient VAT administration and export competitiveness are complementary rather than contradictory objectives. Egypt’s 45-day refund processing timeline demonstrates structured tax administration can support exporters without compromising revenue collection or creating fraud vulnerabilities. Most developed economies maintain even shorter timelines, recognizing delays impose financing costs on exporters that directly reduce competitiveness.

Kenya’s multi-month delays effectively function as forced interest-free loans from manufacturers to government, extracting working capital from private sector and transferring it to public coffers in ways legislative intent never envisioned. For export-oriented manufacturers operating on thin margins characteristic of globally competitive industries, refund delays can render otherwise viable businesses unprofitable by tying up capital that should finance inventory, equipment, and payroll.

Resolving the tension requires viewing efficient VAT refund processing not as fiscal burden but as industrial competitiveness investment that generates returns through expanded exports, increased employment, higher corporate tax revenues from growing profitable businesses, and reduced import dependency strengthening foreign exchange position. This perspective shift from viewing refunds as costs to recognizing them as investments could unlock political will for systemic administrative reforms.

Path Forward Demands Coordinated Reform Implementation

Realizing Kenya’s industrial potential requires coordinated action across multiple policy domains rather than isolated interventions on individual issues. On VAT refunds specifically, solutions demand significant Kenya Revenue Authority information system investments enabling automated verification and risk-based processing, clear service standards communicating expected timelines and recourse mechanisms, adequate Treasury budget allocations ensuring refunds are funded as they become due, and streamlined procedures reducing documentation requirements for established exporters with clean compliance records.

Beyond refunds, manufacturers need stable tax policy environment limiting changes to scheduled comprehensive reviews rather than continuous tinkering, extensive industry consultation before major changes, grandfathering provisions protecting existing investments from retroactive rule changes, and clear explanatory materials helping manufacturers understand and comply with obligations.

Geographic diversification achieving more even manufacturing distribution requires addressing infrastructure gaps in secondary counties through targeted transport corridor development, reliable electricity provision including renewable energy options, broadband connectivity supporting modern business operations, and water/sanitation systems adequate for industrial users. Special economic zones or industrial parks in strategic secondary counties could create enabling environments overcoming some infrastructure deficits through coordinated investment.

The data credibility challenge demands building statistical systems commanding confidence from both government and industry through industry-specific collection protocols, third-party verification of key statistics, transparent methodologies accessible to all stakeholders, and regular reconciliation exercises addressing discrepancies across data sources.

Conclusion: Industrial Policy at Critical Juncture

CS Kinyanjui’s intervention at Sawela Lodge demanding urgent VAT refund release and addressing industrial development challenges signals important political prioritization of manufacturing sector concerns. However, translating ministerial commitment into Treasury budget allocations, KRA administrative improvements, infrastructure investments, and policy reforms requires sustained pressure, accountability mechanisms, and cross-ministry coordination that often proves elusive in government systems.

Manufacturers and potential investors are watching closely to determine whether rhetoric about industrial development translates into concrete improvements in operating environment or merely represents another round of unfulfilled commitments. The extreme geographic concentration of 90 percent of manufacturing in six counties demonstrates that current policy mix has failed to create conditions for broad-based industrial development across Kenya’s territory.

The coming months will reveal whether genuine reform momentum can be sustained addressing VAT refunds, tax policy stability, infrastructure deficits, and regulatory efficiency, or whether familiar structural constraints reassert themselves limiting Kenya’s manufacturing potential. The stakes extend beyond individual sectors or companies—they involve Kenya’s fundamental economic transformation prospects and ability to generate employment for rapidly growing youthful population through industrialization rather than continued dependency on agriculture and services alone.

For floriculture, tea, textiles, and other export sectors, competitiveness in global markets depends not just on natural advantages or entrepreneurial energy but on policy environments and administrative systems that enable rather than obstruct productive activity. Kenya possesses the raw ingredients for industrial success but must demonstrate capacity to execute reforms translating potential into performance. The window of opportunity created by favorable global trade dynamics and China’s market opening may not remain open indefinitely if policy execution continues lagging strategic vision.

Ready to take your career to the next level? Join our Online courses: ACCA, HESI A2, ATI TEAS 7 , HESI EXIT , NCLEX – RN and NCLEX – PN, Financial Literacy!🌟 Dive into a world of opportunities and empower yourself for success. Explore more at Serrari Ed and start your exciting journey today! ✨

Track GDP, Inflation and Central Bank rates for top African markets with Serrari’s comparator tool.

See today’s Treasury bonds and Money market funds movement across financial service providers in Kenya, using Serrari’s comparator tools.

photo source: Google

By: Montel Kamau

Serrari Financial Analyst

27th January, 2026

Article, Financial and News Disclaimer

The Value of a Financial Advisor

While this article offers valuable insights, it is essential to recognize that personal finance can be highly complex and unique to each individual. A financial advisor provides professional expertise and personalized guidance to help you make well-informed decisions tailored to your specific circumstances and goals.

Beyond offering knowledge, a financial advisor serves as a trusted partner to help you stay disciplined, avoid common pitfalls, and remain focused on your long-term objectives. Their perspective and experience can complement your own efforts, enhancing your financial well-being and ensuring a more confident approach to managing your finances.

Disclaimer: This article is for informational purposes only and does not constitute financial advice. Readers are encouraged to consult a licensed financial advisor to obtain guidance specific to their financial situation.

Article and News Disclaimer

The information provided on www.serrarigroup.com is for general informational purposes only. While we strive to keep the information up to date and accurate, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability, or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

www.serrarigroup.com is not responsible for any errors or omissions, or for the results obtained from the use of this information. All information on the website is provided on an as-is basis, with no guarantee of completeness, accuracy, timeliness, or of the results obtained from the use of this information, and without warranty of any kind, express or implied, including but not limited to warranties of performance, merchantability, and fitness for a particular purpose.

In no event will www.serrarigroup.com be liable to you or anyone else for any decision made or action taken in reliance on the information provided on the website or for any consequential, special, or similar damages, even if advised of the possibility of such damages.

The articles, news, and information presented on www.serrarigroup.com reflect the opinions of the respective authors and contributors and do not necessarily represent the views of the website or its management. Any views or opinions expressed are solely those of the individual authors and do not represent the website's views or opinions as a whole.

The content on www.serrarigroup.com may include links to external websites, which are provided for convenience and informational purposes only. We have no control over the nature, content, and availability of those sites. The inclusion of any links does not necessarily imply a recommendation or endorsement of the views expressed within them.

Every effort is made to keep the website up and running smoothly. However, www.serrarigroup.com takes no responsibility for, and will not be liable for, the website being temporarily unavailable due to technical issues beyond our control.

Please note that laws, regulations, and information can change rapidly, and we advise you to conduct further research and seek professional advice when necessary.

By using www.serrarigroup.com, you agree to this disclaimer and its terms. If you do not agree with this disclaimer, please do not use the website.

www.serrarigroup.com, reserves the right to update, modify, or remove any part of this disclaimer without prior notice. It is your responsibility to review this disclaimer periodically for changes.

Serrari Group 2025